Multiple Rope Mining Hoist Rope Smart Inspection Expert System

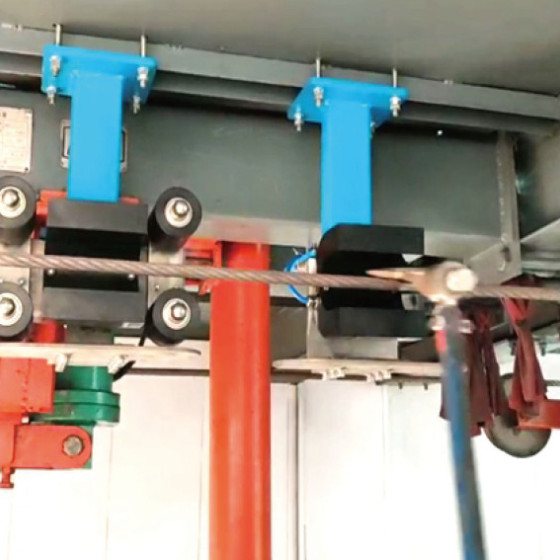

TCK.W magnetic memory wire rope Al weak magnetic

inspection technology fully uses the characteristic of

magnetic memory of Ferro-magnetic material. It

actively regulates a memory magnetic field with

appropriate quantity. It uses wide air gap and noncontact

weak magnetic sensing technology and Al

technology. By collecting magnetic energy potential

differential information distributed and memorized in

wire rope volume element, it can inspect online, realtime,

automatically all kinds of hidden dangers of wire

rope such as broken wire, abrasion. corrosion and

fatigue during the rope operation.

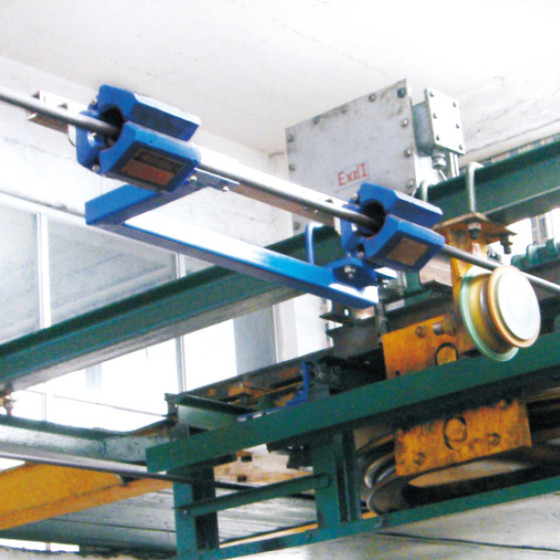

This brand-new technology not only sets a precedent

for replacing manual inspection with machine

intelligence inspection, but also helps users improve

wire rope safety to the highest level. Moreover, it can

create great value for customers in terms of security

management, cost reduction and efficiency increase.

TCK.W has 34 core technology patents, 3 invention

patents from the United States, the European Union

and Japan, and 24 software Copyrights.

- Information

IOT+ 5G+ WIRE ROPE INTELLIGENT MONITORING PLATFORM

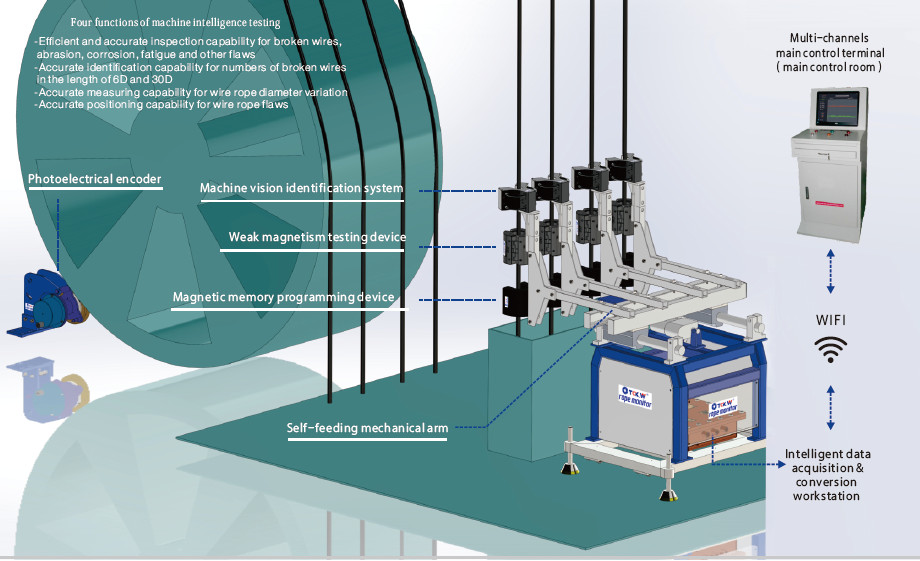

1、Mining Hoist Status Overview for Bayangale coal mine

The main hoist of Bayan Gaole mine is a 4-rope floor type friction hoist, whose height is 595 meters with lifting speed of 10.37 m/s in

the production process and lifting time of about 3 minutes.

The lifting amount of a full cycle is 38 tons times two. The motor power of the hoist is 5000kW·h, with 20 lift cycles per hour and 360

working days per year.

2、TCK. W system applications

1.Wire rope safety has been raised to the highest level

Realize the replacement of manual inspect with machine intelligent inspection. Complete 24 hours X 365 days wire rope full life cycle

safety monitoring. Wire rope safety hazards can be found in a timely manner and completely eliminated rope breakage accidents.

2.Complete the intelligent monitoring of big data at the same time of production, which is costs reduction and efficiency improvement.

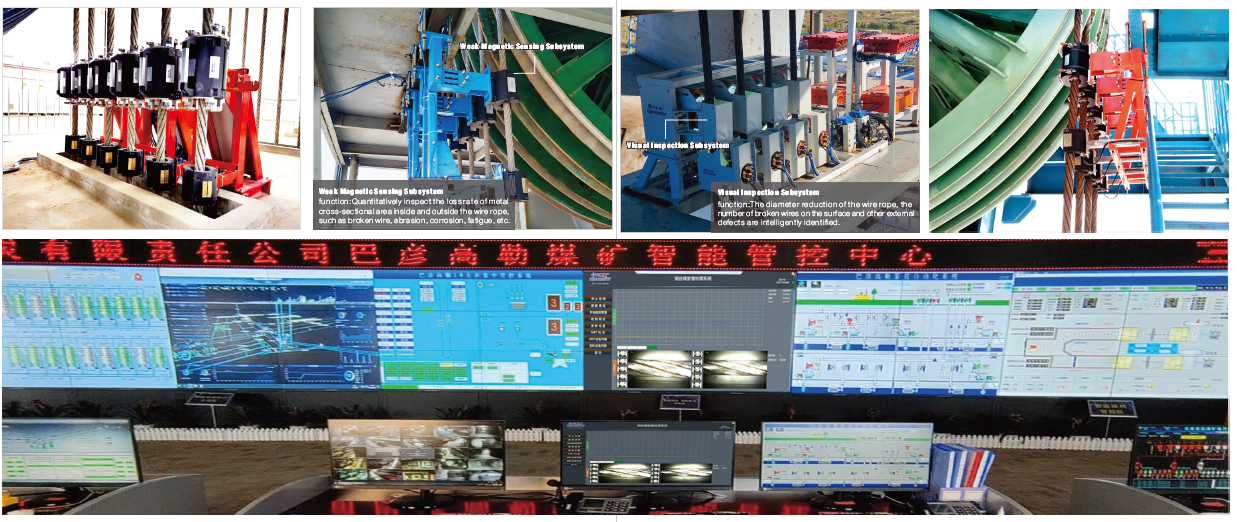

2.1 According to the Coal Mine Safety Regulations, the lifting of wire ropes must be checked once a day.

2.2 The mine inspector inspects the wire rope once a day at a speed of 0.5m/s and takes 0.5h. One inspection needs energy consumption

of 2500Kw, which reduces 10 lift cycles namely 760 tons. The annual inspection time is about 180h, with energy consumption of 900,000 kW.h,

reducing 3600 lift cycles, namely 273.6 million tons. Based on the current price of 1760 CHY per ton of coal, the annual output value

will be reduced by 481.5 million CHY.

2.3 With TCK.W system, the mine can be realized with monitoring at the same time as production. The annual reduction of shutdown

time will be 180 hours, during which 273.6 million tons of raw coal can be increased , namely output value of nearly 481.5 million CHY.

2.4 Save 900,000 kW·h of power consumption special for wire rope inspection, and save electricity costs of 369,000 CHY.

3、Significant energy-saving and emission-reduction effects, helping to achieve the dual-carbon goal

The annual energy consumption used for rope inspection at the Bayangaole Mine, China is 900,000 kW.h, which has invisibly increased

carbon dioxide emissions by 897,300 kg. After using the TCK.W inspection system, it can save 900,000 kW.h of energy consumption for

rope testing and 897,300 kg of carbon dioxide emissions throughout the year, providing a strong technical guarantee for the realization

of the "Dual Carbon" goal.

4、Save the cost of rope and provide technical catch for protecting the environment.

The cost of use of rope in Bayangaole Mine, China is 1,722,100 CHY, and the rope replacement period is 2 years. The average annual

cost of ropes is 860,000 CHY, and there may be waste of wire ropes. According to the coal mine safety regulations, after 2 years of use,

the wire rope can continue to be used for 1 year if the number of broken wire rope, the rope diameter reduction, and the degree of corrosion

do not exceed the regulations. We believe that the TCK.W intelligent monitoring system may prolong the service life of wire ropes by at

least one year and reduce the cost of ropes by one third while ensuring safety. The annual cost of ropes can be reduced from 860,000

CHY to 570,000 CHY; the average cost of ropes each time is reduced by 860,000 CHY.

We believe that under the state of intelligent monitoring of the TCK.W equipment for the wire rope of the Bayangaole Mine, China, the

safety development trend of the wire rope can be fully mastered, and it is entirely possible to save the amount of wire rope and reduce

the cost of the rope under the premise of ensuring the safety of the wire rope. And this will contribute to perform President Xi Jinping's

solemn commitment to the “3060 dual-carbon target” put forward by the Chinese government at the United Nations Global Climate

Conference and for the circular economy, resource protection, and environmental protection.