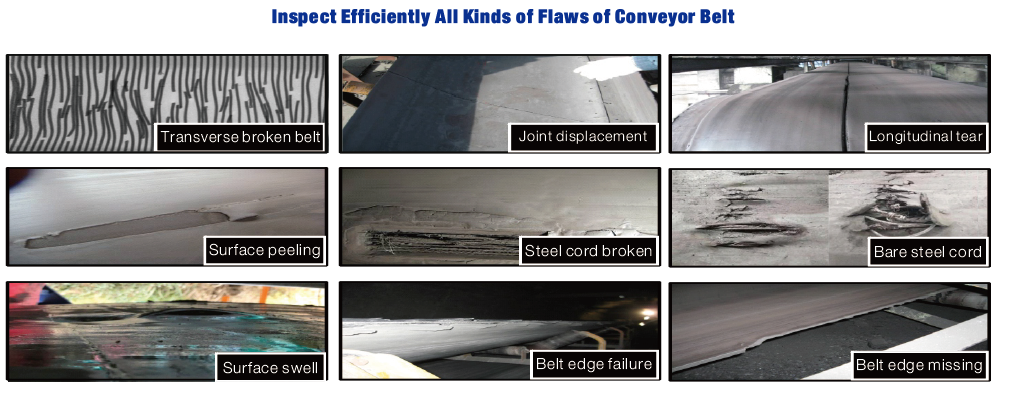

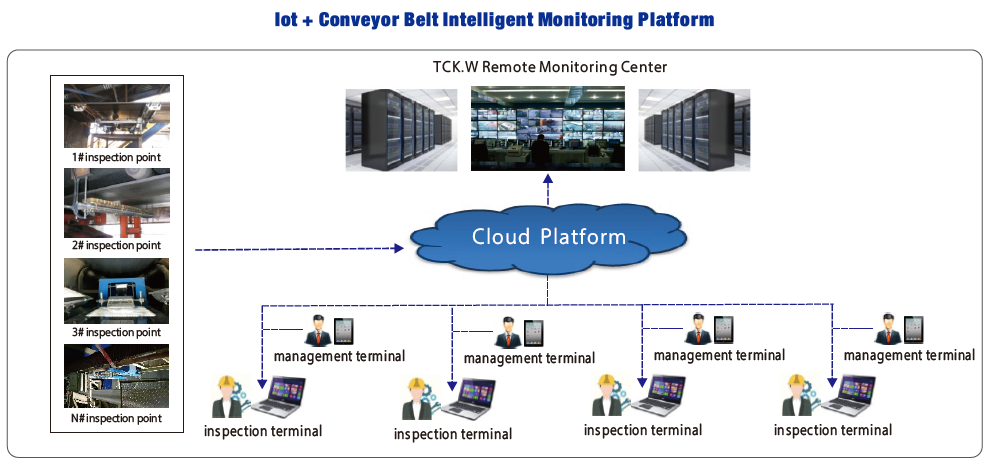

Steel Core Conveyor Belt Intelligent Monitoring System

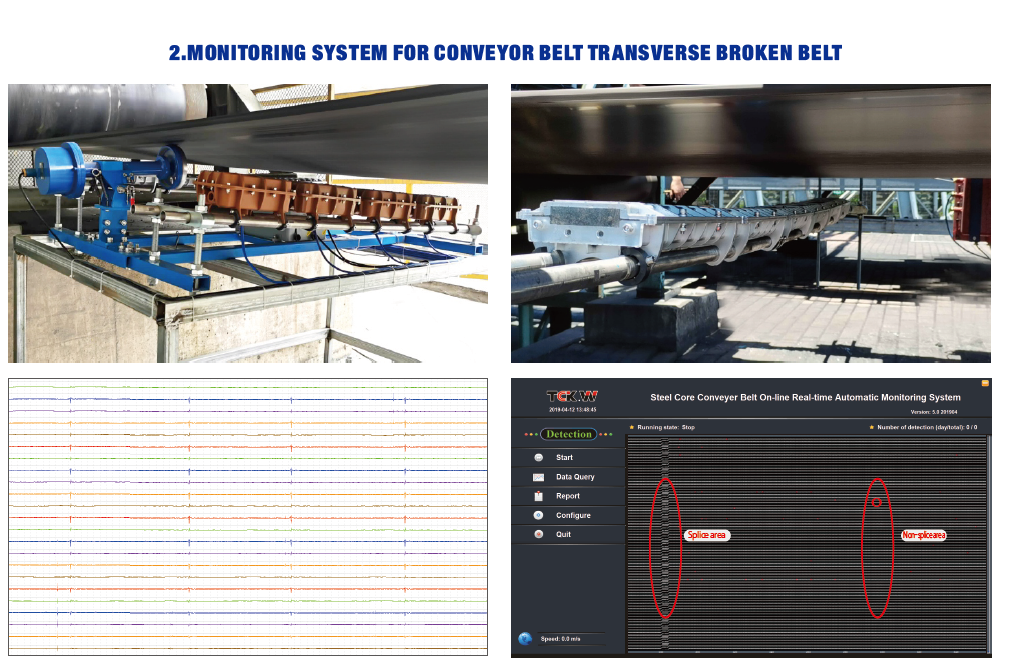

The broken belts all occur at the splice and there are no exceptions to the case of broken belts at home and abroad.

The splice of conveyor belt is the weakest part of the whole belt that can endure the lowest compressive strength.

There are many reasons for splice breakage: incorrect coating, wrong pressing temperature or pressure, corrosion of steel cord

ends, severe scratches, strain, etc. Regardless of which cause of the splice damage or broken, it must be accompanied by an increase

in the amount of deformation in the splice area and the occurrence of steel cord twitch.

After the local steel cord twitch in the splice area, the entire working load will be concentrated on the non-twitch steel cords.

With the passing of time, the number of locally twitched steel cords increases and the area continues to expand. The plastic deformation

of the joint becomes larger and larger, and the rigidity and strength become lower and lower. Finally, when the range of the twitched

steel cords in the splice and its deformation increase to a certain degree, the bonding layer between the steel cord and the rubber

encounters serious damage, and when the bonding force is not enough to withstand the working load, all the steel cords were pulled

out bare, forming a splice fracture.

- Information

The Mechanism of Transverse Broken Belt

MONITORING SYSTEM FOR CONVEYOR BELT TRANSVERSE BROKEN BELT

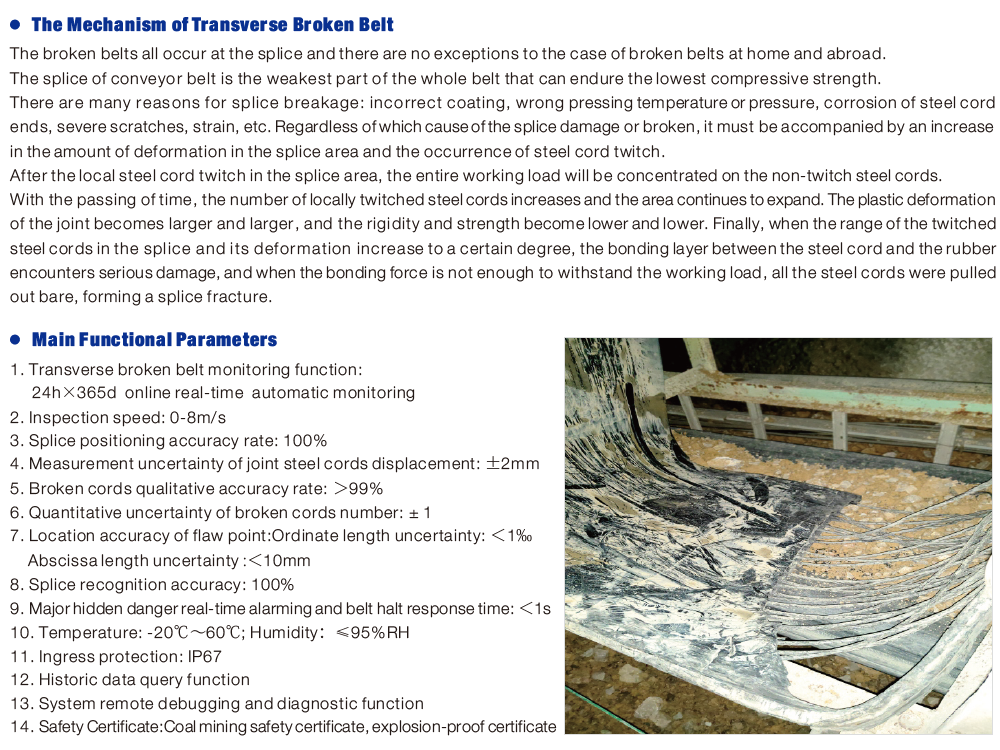

The broken belts all occur at the splice and there are no exceptions to the case of broken belts at home and abroad.

The splice of conveyor belt is the weakest part of the whole belt that can endure the lowest compressive strength.

There are many reasons for splice breakage: incorrect coating, wrong pressing temperature or pressure, corrosion of steel cord

ends, severe scratches, strain, etc. Regardless of which cause of the splice damage or broken, it must be accompanied by an increase

in the amount of deformation in the splice area and the occurrence of steel cord twitch.

After the local steel cord twitch in the splice area, the entire working load will be concentrated on the non-twitch steel cords.

With the passing of time, the number of locally twitched steel cords increases and the area continues to expand. The plastic deformation

of the joint becomes larger and larger, and the rigidity and strength become lower and lower. Finally, when the range of the twitched

steel cords in the splice and its deformation increase to a certain degree, the bonding layer between the steel cord and the rubber

encounters serious damage, and when the bonding force is not enough to withstand the working load, all the steel cords were pulled

out bare, forming a splice fracture.

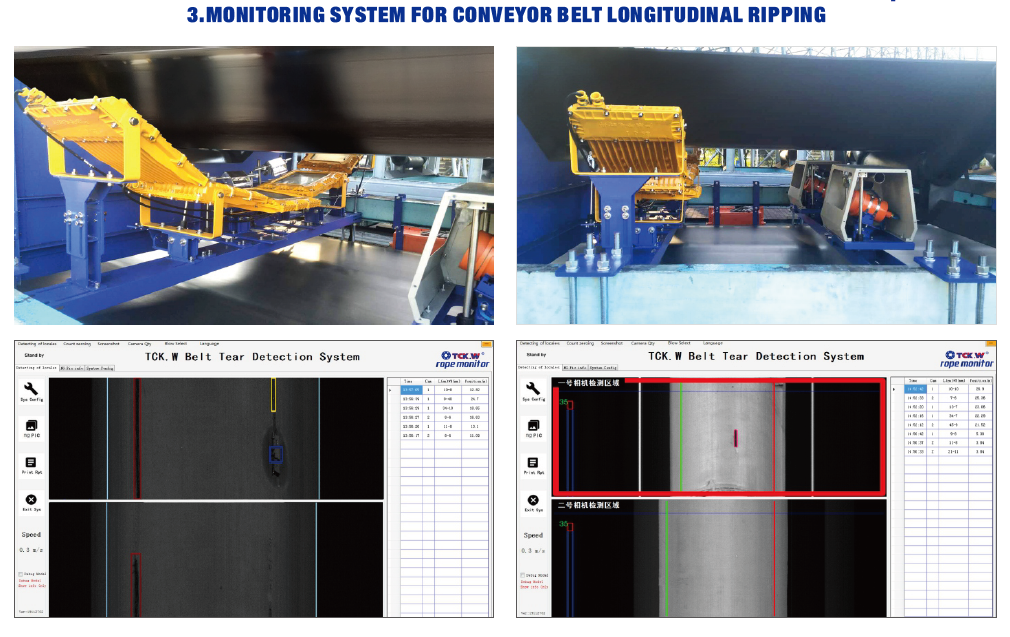

Main Functional Parameters

1. Transverse broken belt monitoring function:

24h×365d online real-time automatic monitoring

2. Inspection speed: 0-8m/s

3. Splice positioning accuracy rate: 100%

4. Measurement uncertainty of joint steel cords displacement: ±2mm

5. Broken cords qualitative accuracy rate: >99%

6. Quantitative uncertainty of broken cords number: ± 1

7. Location accuracy of flaw point:Ordinate length uncertainty: <1‰

Abscissa length uncertainty :<10mm

8. Splice recognition accuracy: 100%

9. Major hidden danger real-time alarming and belt halt response time: <1s

10. Temperature: -20℃~60℃; Humidity:≤95%RH

11. Ingress protection: IP67

12. Historic data query function

13. System remote debugging and diagnostic function

14. Safety Certificate:Coal mining safety certificate, explosion-proof certificate

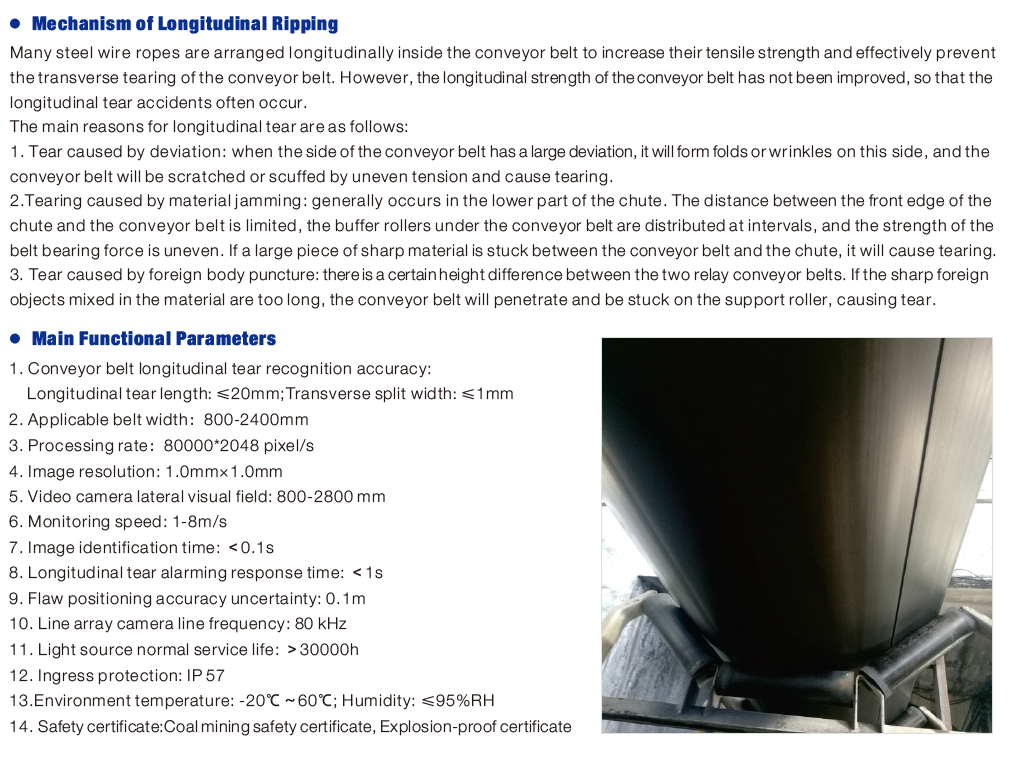

Many steel wire ropes are arranged longitudinally inside the conveyor belt to increase their tensile strength and effectively prevent

the transverse tearing of the conveyor belt. However, the longitudinal strength of the conveyor belt has not been improved, so that the

longitudinal tear accidents often occur.

The main reasons for longitudinal tear are as follows:

1. Tear caused by deviation: when the side of the conveyor belt has a large deviation, it will form folds or wrinkles on this side, and the

conveyor belt will be scratched or scuffed by uneven tension and cause tearing.

2.Tearing caused by material jamming: generally occurs in the lower part of the chute. The distance between the front edge of the

chute and the conveyor belt is limited, the buffer rollers under the conveyor belt are distributed at intervals, and the strength of the

belt bearing force is uneven. If a large piece of sharp material is stuck between the conveyor belt and the chute, it will cause tearing.

3. Tear caused by foreign body puncture: there is a certain height difference between the two relay conveyor belts. If the sharp foreign

objects mixed in the material are too long, the conveyor belt will penetrate and be stuck on the support roller, causing tear.

. Conveyor belt longitudinal tear recognition accuracy:

Main Functional Parameters

1 Longitudinal tear length: ≤20mm;Transverse split width: ≤1mm

2. Applicable belt width:800-2400mm

3. Processing rate:80000*2048 pixel/s

4. Image resolution: 1.0mm×1.0mm

5. Video camera lateral visual field: 800-2800 mm

6. Monitoring speed: 1-8m/s

7. Image identification time: <0.1s

8. Longitudinal tear alarming response time: <1s

9. Flaw positioning accuracy uncertainty: 0.1m

10. Line array camera line frequency: 80 kHz

11. Light source normal service life: >30000h

12. Ingress protection: IP 57

13.Environment temperature: -20℃∼60℃; Humidity: ≤95%RH

14. Safety certificate:Coal mining safety certificate, Explosion-proof certificate