Magnetic Rope Testing Device

Wire rope - stepping out of the safety regulation blind spot The TCK.W smart detection system for wire rope uses wide spacing, ultra-high speed, and non-contact memory magnetic field AI weak magnetic perception technology, which will completely change the traditional periodic visual inspection method. It can detect, monitor, evaluate, warn and dispose of various safety hazards such as broken wires, wear, rust, and fatigue that occur during the operation of critical equipment and important facilities' wire ropes 24/7. For the first time, it achieves daily reporting of the wire rope's safety status, regular evaluation of damage development trends, real-time warning of safety hazards, and remote monitoring throughout the lifecycle, elevating wire rope safety to the highest level.

- Information

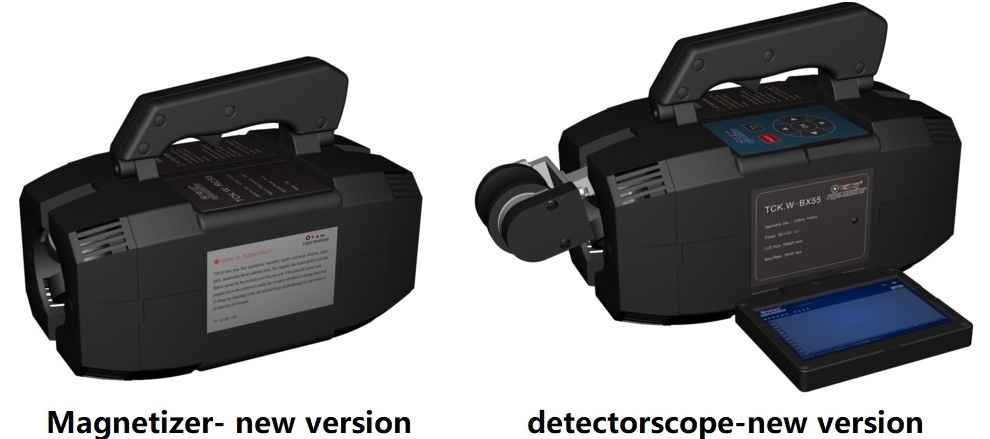

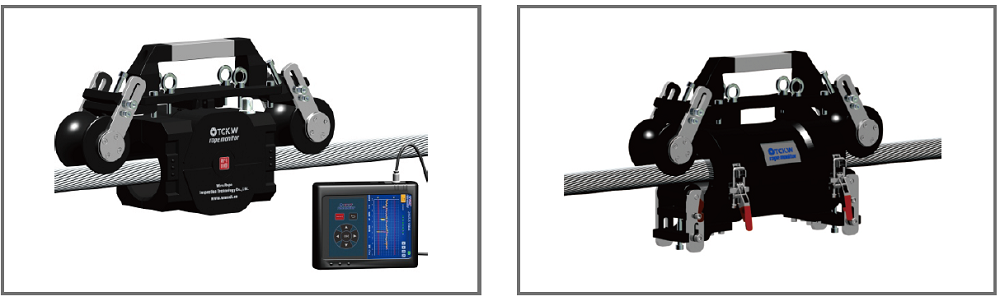

Smart Wire Rope Inspection Equipment-5G

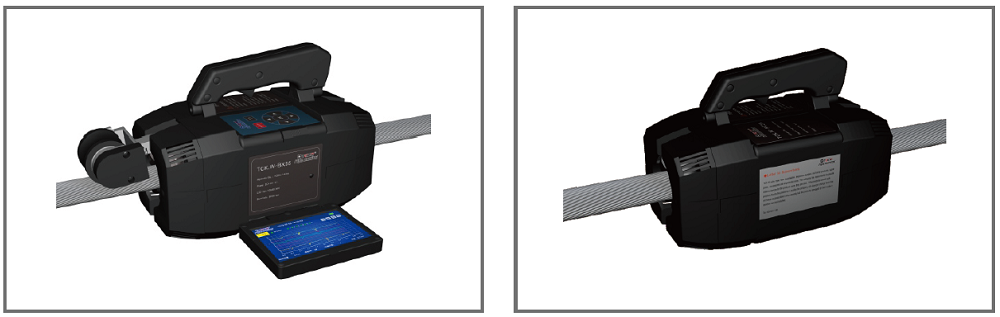

Protable Wire Rope Inspection Device-4G

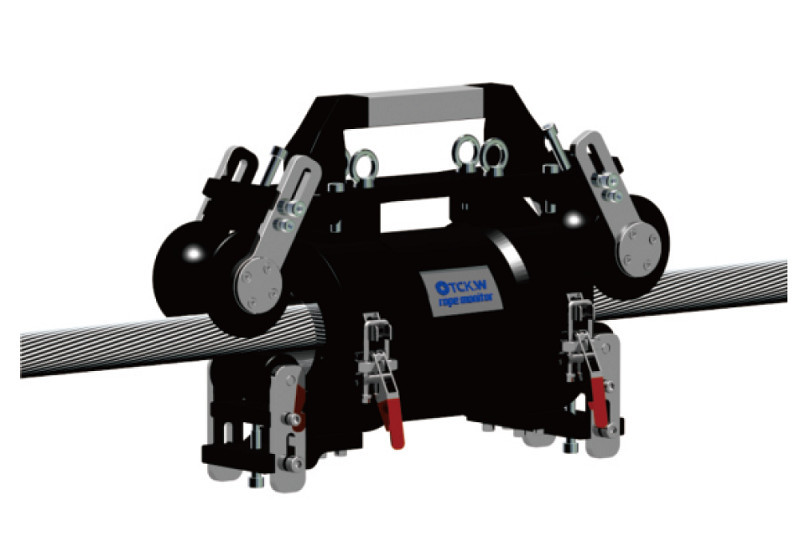

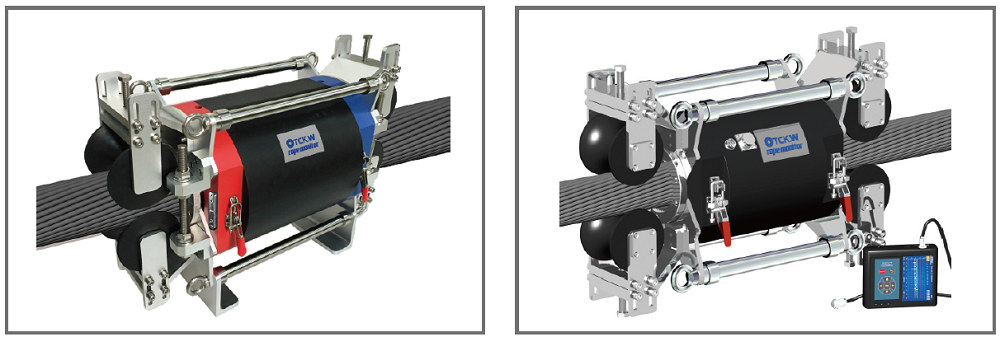

Super Large Diameter Wire Rope Inspection Equipment-5G

| Model | Diameter of wire rope(mm) | Dimension (LxWxH) (mm) |

| TCK.W-BX40-4G | 16-26 | 316X178X195(D) 267X155X195(M) |

| TCK.W-BX55-4G | 26-42 | 316X178X195(D) 460X193X301(M) |

| TCK.W-BX65-4G | 36-52 | 316X178X195(D) 460X193X301(M) |

| TCK.W-ZN0838-5G | 8-38 | 38 430X130X263(D) 460X193X301(M) |

| TCK.W-ZN3560-5G | 35-60 | 430X130X263(D) 465X231X324 (M) |

| TCK.W-ZN6080-5G | 60-80 | 546X243X400(D) 546X243X400(M) |

| TCK.W-ZN80120-5G | 80-120 | Customized |

Technical Parameters

1. Inspection function: quantitative inspection on broken wires,abrasion, corrosion and fatigue.

2. LMA of MRT Inspection uncertainty :≤±1%

3. Flaw positioning accuracy:≥99%

4. Automatic benchmarking function: adapt to benchmarking forvaried wire rope and automatic benchmarking once on singlepoint location without need to benchmark at multiple positionsfor multiple times.

5. Self-diagnosis function: have self-diagnosis function for sensorproperty, communication modular, storage modular, AD/DAmodular and remaining capacity.

6. Emergency unlock of device: personnel and device can beguaranteed by withdrawing rapidly with unlock time<1 second;

7. Operation model: equipped with wide color touch screen and key pad with key membrane. Support dual mode operation.

8. Display function: wide color touch screen to display inspection curve during inspection.

9. Retrieval function: can retrieve inspection content on real-time through touch screen, including current curve of wire rope, flaw position, flaw quantity list. Historic inspection data can also be retrieved.

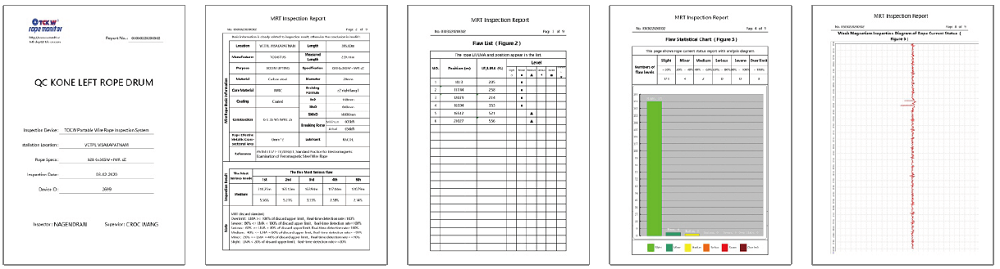

10. Report function: By connecting with computer through Wi-Fi, inspection report can be printed out instantly. Can also print inspection report of any historic point whenever necessary. Inspection report is automatically generated by software and easy to be read and interpreted.

11. Magnetic memory regulation device: self- contained unit with function of regulating memorized magnetic fie l d . M e m orized magnetic field can be maintained forever if no external interference.

12. Inspection device: self- contained unit with non-contact weak magnetic sensor array. Can collect magnetic energy potential differential information in wire rope and analyze quantitatively without connecting external operation system.

13. Data storage: 64G Class 10 high speed flash memory can support saving maximum 50,000 meters long wire rope for single inspection. Storage supports saving 1,000 inspections for 10,000 meter/time.

14. Passing-through capability: air gap between sensor and wire rope: 10-30mm

15. Inspection speed: 0-3m/s. Not affected by surface warp, oil and deformation.

16. Data transmission: Wifi transmission or USB transmission.

17. Sensitivity of sensor: 1.5V/mT

18. Electric magnetic sensing signal-to-noise ratio: S/N>85dB

19. Maximum Sampling rate: 1024 times/m

20. Rated working voltage: Power supply by Lithium battery, DC 7.4 V

21. Continuous operation hours of battery:≥6hours

22. Ingress protection:IP53

23. Working environment: -20℃-+55℃; RH 95%

Flaw detectability:

● Severe flaw: LMA reaches 80%-100% of discard upper limit, real-time detectability 100%

● Serious flaw: LMA reaches 60%-80% of discard upper limit, real-time detectability 100%

● Medium flaw: LMA reaches 40%-60% of discard upper limit, real-time detectability 100%

● Minor flaw: LMA reaches 20%-40% of discard upper limit, real-time detectability >99%

● Slight flaw: LMA reaches 20% of discard upper limit, real-time detectability >95%

Inspection repeatability:

● Severe flaw: 100%

● Serious flaw: 100%

● Medium flaw: 100%

● Minor flaw: >99%

● Slight flaw: >95%

Inspection Accuracy:

●LMA inspection uncertainty: <±1%;Broken wires q ● uantitative error in one lay length: <1 wire*

●Wire rope dia. measure error: ±1%*

●Measuring error of wire rope length:<0.2%

●Flaw positioning accuracy:≥99%;

Internationally leading detection technology The TCK.W technology has solved a century-old problem that has plagued the global wire rope non-destructive testing industry. It is a change in the original technical path, with a revolutionary effect that can change traditional game rules, leading to disruptive innovative technologies. TCK.W has won the top award in the 2022 China Ministry of Science and Technology's Disruptive Technology Competition, the 2022 China Equipment Management Technology Innovation First Prize, the 2019 Singapore PSA Technology Progress Bronze Award, and the 2018 US Offshore Technology Conference Spotlight on New Technology Innovation Award.

An important part of the human safety ecosystem The TCK.W series of products have been widely used in mines, ports, oil, offshore engineering, ships, construction, steel and metallurgy, national defense, military industry, lifting machinery, elevators, cable cars, and cable-stayed bridges in many countries worldwide, including China, the United States, the European Union, Japan, Singapore, and South Korea. The mission of TCK.W is to become an important part of the human safety ecosystem, making the production process and daily travel safer.

Test Report